Wall Mounted Pegboard

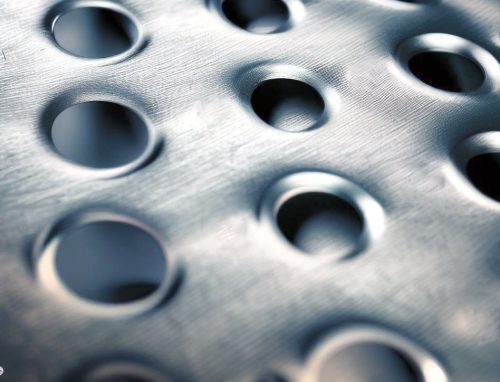

You can place the wall mounted pegboard anywhere – kitchen, living room, bedroom. With shelves and hooks of different sizes, our wall mouned pegboard can become photo walls, bookshelves, display boards, jewelry organzier, etc. The metal toner coating can protect the metal sheet from rusting and abrasion. Compared with plastic and wood, metal materials are more heat-resistant and not deformed!

Still can’t find the ideal pegboard?

Contact DODO+

Wall Mounted Pegboards For Home Storage

In the 21st century, with the increasing awareness of environmental protection and the growing demand for home storage solutions, metal pegboards have gradually entered the household sector. Metal pegboards are now available in a variety of colors and shapes, and the focus is increasingly on personalization and aesthetics.

Metal pegboards can be classified into three main types: household, commercial, and industrial, depending on their intended use and material. Initially, metal pegboards were primarily used in construction, such as roofs and partition walls, before people started to use them in garages and factory buildings. Common materials for wall-mounted pegboards include plastic, wood, and galvanized metal sheets. Due to their material characteristics, plastic and wood pegboards are relatively limited in terms of their application scenarios.

Galvanized metal pegboards made of iron offer a certain level of strength and durability. The metal pegboards feature a protective zinc coating on their surface that provides excellent corrosion resistance, making them ideal for use in humid environments.

Metal pegboards are an excellent storage solution for kitchens, because they can withstand high temperatures of 200-230 degrees Celsius and possess fire-resistant characteristics. Also, the smooth surface and moisture-resistant properties of the metal pegboard make it easy to clean the kitchen oil fume.

DODO+ metal pegboards are made of 1.2mm-thick iron sheets, which are more robust and durable compared to wooden or plastic pegboards, with a longer service life.

Quick Q&A

Q: What are the dimensions of wall mounted metal pegboard?

A: 740/370/185x370mm, 418x640mm, 715x350x120mm,660*465mm

Q: Can we add our company’s logo or brand to the metal pegboard?

A: Custom logo can be added to the pegboard! MOQ is 500 pieces.

Q: What are the installation methods of wall mounted pegboard?

A: Expansion screws require the use of an electric drill and hammer. If using non marking nails, you need to prepare a hammer. The strong adhesive hook requires no tools.

Q: What is the production time of the metal pegboard?

A: Order from stock, quantity less than 500 pieces, delivery time 20 days. Customized pegboards or packaging, with a quantity of 500-1000 pieces and a production time of 45-50 days.

Q: How much can the wall mounted metal pegboard bears?

A: Depending on the installation method and the matching shelf. If installed with expansion screws, combined with a screw type shelf, it can bear about 20kg (including the weight of pegboards).

Q: If we need the metal pegboard to have a specific color or appearance, can we customize it?

A: Sure! The following are customization requirements: Customize regular shapes and colors, such as white, black, and green rectangular metal pegboards, with a MOQ of 1000 pieces.

Start A New Project With Us!

Send your quotation request to us, and we will generate a quotation that meets your requirements for your metal pegboard project.

Follow on Social

Cooperate With Metal pegboard manufacturer

Pegboard Design

We attach great importance to the protection of intellectual property rights and have patented our products.

Process Technology

The powder coating has better chemical resistance and durability, and is conducive to the realization of super-environmental health concept.

Warehouse Support

We offer pick-and-pack services for quick and accurate order fulfillment. Our comprehensive storage solutions are designed to meet our clients’ needs.

Customized Services

To meet the unique needs of our customers, we provide customized services. Our custom services include metal pegboard, packaging, specifications and so on.

Exploring The Manufacturing Techniques For Metal Pegboard

Introducing our metal pegboard – the ultimate storage solution for organizing any workspace! Our expertly crafted metal pegboards are manufactured using advanced production processes and techniques, guaranteeing unparalleled durability and functionality.

We take pride in our streamlined manufacturing process, which ensures top-quality construction and durability. With our metal pegboard, you won’t have to worry about sagging or warping over time.

Discover the exceptional craftsmanship that goes into our metal pegboard and the convenience it provides for organizing your daily life. Read on to learn more.

Metal Laser Cutting Process

Sheet metal laser cutting technology is an advanced processing technology and technique that is highly efficient, high-energy, and highly flexible. The laser-focused light spot has a very small direct area, which can be used for narrow slit, micro-hole, and other work. Laser cutting can cut almost all materials, including two-dimensional or three-dimensional cutting of thin metal sheets.

As a non-contact processing method that does not require cutting tools, it has good material adaptability and a long effective life, and therefore does not cause mechanical deformation during processing. The advantages of laser cutting are mainly reflected in the smooth processing of high-precision and high-quality work, effectively reducing costs, improving production efficiency, and shortening product production cycles.

Whether it is a simple or complex sheet metal part, it can be precision cut with laser for rapid forming, with narrow cuts and smooth cutting edges. Sheet metal laser cutting technology has a very advanced application advantage in the sheet metal industry and is widely popular.

Metal Powder Spraying Process

In terms of color technology, we have chosen a metal powder spraying process. Powder coating is ideal for casting iron items as it can fill defects and rough surfaces. It also allows for the repair of the metal’s natural flaws, and is resistant to corrosion. With no irritating odors or harmful chemicals, it is also eco-friendly.

There are fundamental differences between metal powder and paint spraying. While the latter uses compressed air to distribute the liquid paint onto the surface, the former employs compressed air to atomize the powder and spray it onto the surface via the electrical field.

Compared to paint spraying, metal powder has a more straightforward application process, lower cost, and no need for primers or thinners. The coatings produced are of high quality, and have excellent adhesion and mechanical strength, as well as resistance to corrosion and wear.